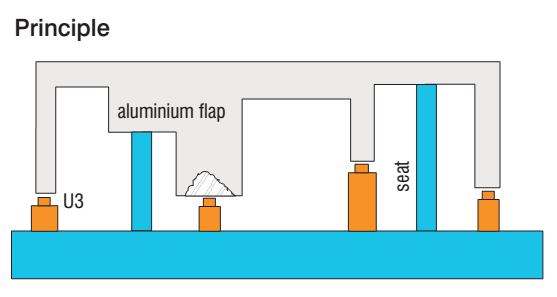

铝制铸件铸造成型以后,进入下一个精加工环节之前,需要手工矫形并判断是否为不合格件。该操作会发生在比较严酷的环境当中(铸造车间)。传统的做法是采用接触式探头,缺点是探头易磨损并需要定期更换。为了解决这个问题,需要采用非接触,无磨损的电涡流测量系统。

After AL covers have been cast and prior to milling of the sealing surface the covers must be manually straightened and sorted into OK/NOK. This operation takes place in a rough environment (casting bay). The measuring technique that was used earlier (probes) are subject to a high degree of wear and had to be replaced in regular intervals.In order to minimise spare parts costs the customers have decided in favour of the non-contacting and non-wearing eddy-current measuring system. What is of special importance for the success of this measuring method is the fact that eddyNCDT eddy-current sensors, due to the possibility of 3-point-linearisation, supply reliable measuring values even with complex target geometries.

您当前的位置:

您当前的位置: